Compressors are used in many industrial segments, starting from manufacturing and construction through the healthcare sector and ending at household appliances. These devices are widely used in many applications because they can dramatically compress a gas by reducing its volume. The basics of compressors and their benefits will help explain why they are such a critical component of today’s technology and industries.

Fundamentally, compressors are machinery that have the primary function of raising the pressure of a given gas, particularly air, through the means of narrowing its space. This is a crucial process in most systems that helps store, transport, and utilize gas. Compressors can be categorized into several types, each suited to specific applications:

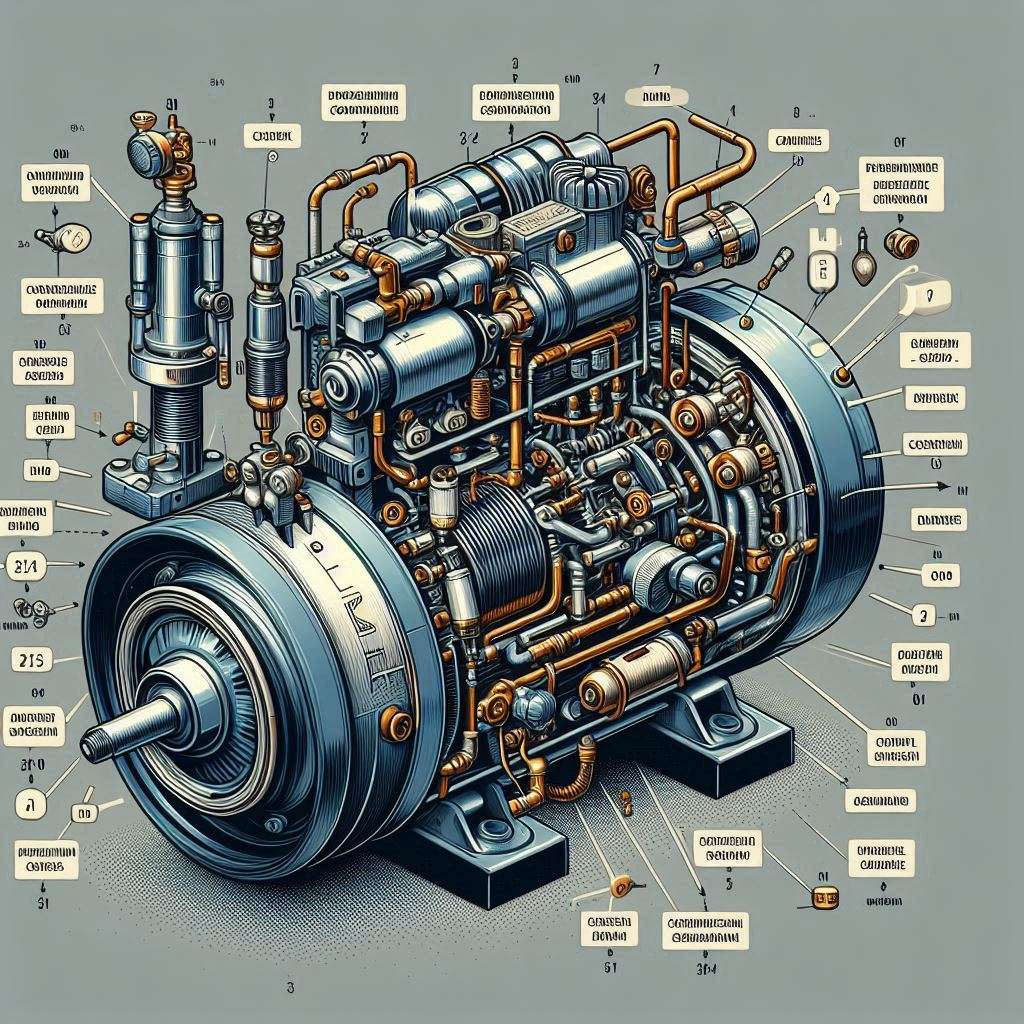

This air compressor produces energy by gradually compressing air stored outside the tank.

Rotary screw compressors:

Rotary screw compressors create energy using an internal rotor system, while two internal rotors rotate in opposite ways. This causes pressure to build up as the air gets caught in between, forming an insulating layer. These machines are usually big. Some of them need oils for lubrication, while others do not require any oil. They are suitable for occupations on a large scale, especially in industrial structures, and can easily endure day use.

Reciprocating compressors:

The reciprocating compressor features an internal system involving a piston within the cylinder displacing and pressuring air. It can be single-stage or multi-stage. Single-stage models can only supply low pressure, while multi-stage models come with high pressure and high power. These are primarily for home use, not as commercial, and can only be used for small-scale projects such as home remodeling.

Given its use in manufacturing, mining, construction, automotive, and other industries, every compressed air process cannot operate without an air compressor. An air compressor offers a steady supply of compressed air to drive most pneumatic tools and equipment. Purchasing good-quality air compressors has many advantages that will assist your business in performing proficiently and economically.

Reliability and Durability

An increased standard of electric air compressors means that the equipment is designed for years of use. It is made from solid materials that can withstand all the industry conditions. It is also built for optimal installation performance, which minimizes the chances of the equipment breaking down. Selecting a good air compressor is vital since it is a crucial tool several organizations need to ensure their operations go as planned.

Energy Efficiency

Energy efficiency is one of the most apparent and probably the most obvious benefits of purchasing quality portable air compressors. These compressors are said to have lower energy consumption than other inferior types, thus lowering your energy bills. They also have more elaborate control mechanisms that precisely control the quantity of compressed air to be manufactured at any one time to avoid waste of energy. Besides, this will make your business establishment use less energy, reducing the overall carbon footprint in society.

Improved Performance

Air compressors with high quality are meant to offer optimum performance all the time. They can deliver a constant and stable supply of compressed air at the desired pressure to make sure that equipment and tools run at their optimal capacity. This can lead to greater effectiveness, quicker throughput, and improved output quality. When you opt for a high-quality vertical air compressor, you invest in the development of your business.

Reduced Maintenance Costs

Cheap air compressors are also known to have many more failures and thus be more delicate regarding repairs and maintenance. This can lead to efficient working time and frequent maintenance, which are expensive when you often have to go through them. A good quality air compressor will not require frequent servicing or part replacement, hence being cheaper to maintain. Such compressors are durable and designed to have minimal service intervals, allowing your operations to go on without interruption.

When choosing an air compressor for your application, you’ll want to keep a few factors in mind:

• Size: They come in many sizes, and one only needs to decide based on the size they want. The compressor should be selected in a manner capable of providing power to the equipment that will be used.

• Portability: Air compressors, which are fixed unit types, are ideal for those searching for air compressors for industrial purposes. Yet, if you are in the construction business, it is highly probable that you will require portable air compressors if you move from one site to another.

• Noise: Certain air compressor models are noisy, which is an area to consider for the project's environment. Some air compressors are noisier than others; therefore, if you have any particular preference regarding which compressor is relatively noiseless, you should base your decision on this aspect.

• Compatibility: One consideration is the compatibility of tools and equipment. It is wise to decide on an air compressor that can supply your existing tools and equipment. Pneumatic tools need a CFM requirement, and depending on what type of air compressor you need, the best one for you will depend on it.

Due to their advantages, compressors are important in many applications across several industries. Their cost-effectiveness and opportunities to increase product performance and quality make them vital in today’s industrial and technological systems. Notably, the future evolution of technology might enhance compressors' performances in terms of efficiency, reliability, and environmental impact; compressors' applicability is likely to become even more widespread.